Product Details

Product Introduction

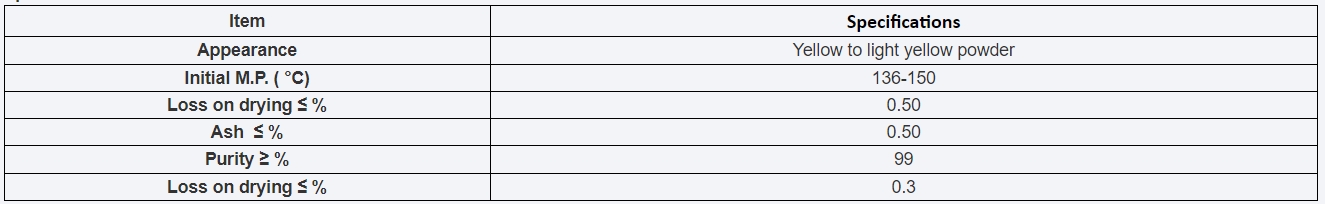

The Rubber Penetrator DBD, formally known as "2,2'-dithiodibenzanilide" (CAS No.: 135-57-9), serves as a highly efficient additive for rubber. Its molecular formula is C26H20N2O2S2, and it has a molecular weight of 456.58. This product is presented as a light yellow powder, characterized by low toxicity and minimal environmental impact. It demonstrates solubility in various organic solvents including benzene, ethanol, and acetone, while remaining insoluble in water. Rubber Penetrator DBD finds its primary application in the formulation of natural rubber, synthetic rubber, or rubber blends. Typically, it is incorporated into emulsions containing crude rubber and is introduced to the mixer promptly following the cracking process. The ideal operating temperature for this additive is around 155°C±5°C, with a suggested dosage ranging from 0.1 to 0.5 parts. The product exhibits strong storage stability, although it is essential to keep it in a dry, cool, and well-ventilated environment to prevent direct sunlight exposure. Available packaging options include 25kg plastic woven bags, paper plastic film bags, and kraft paper bags, which facilitate convenient transportation and storage.

Advantages and features

1. Exceptional efficiency: The DBD rubber penetration machine demonstrates outstanding penetration capabilities during the rubber preparation stage, leading to a substantial enhancement in product quality. 2. Eco-friendly and non-polluting: This machine is characterized by low toxicity and zero pollution, ensuring a safe production environment while aligning with green development principles. 3. Versatile solvent compatibility: It is soluble in various organic solvents, including benzene, ethanol, and acetone, making it user-friendly and adaptable to different needs. 4. Remarkable stability: The product maintains excellent storage stability, allowing it to be kept for extended periods in a dry, cool, and well-ventilated space without any degradation in quality.

Application Scenario

1. Natural rubber: Suitable for formulating natural rubber to enhance product performance. 2. Synthetic rubber: Commonly utilized in the formulation of synthetic rubber to improve product permeability. 3. Alloy rubber: Suitable for emulsified formulations containing crude rubber to elevate quality and effectiveness.

.png)